About this deal

Leakage and seal problems - when new chemistry is added to a machine and/or a violent flushing occurs, seal performance may be affected. This may also be due to changes in lubricant viscosity or interfacial intension from fluid mixing problems.

flush out a 75W/90 manual gearbox — MoneySavingExpert How to flush out a 75W/90 manual gearbox — MoneySavingExpert

We’ve seen an example of the oil service life in a large ship’s pitch propeller hydraulic fluid sump being decreased drastically. Usually, the R&O fluid lasted for five years but after the first drain and refill (without flushing the sump), the oil life was reduced to three years! Afterwards, the drain and refill was repeated (without the flush again) and this time the oil life reduced to one year ! If this is the case for your engine, it is definitely not worth using an engine flush. You would find it best to leave well enough alone and not disturb the sludge that may be the only real barrier keeping oil from leaking past the seals in the older engine. If you do use it in this situation, you could end up with a leaking engine or worse. So is engine flush worth it? The flushing process may be perceived to be an expensive, complicated and time-consuming extra task for an oil change. However, some conditions justify the effort. Highly contaminated reservoirs on critical systems warrant additional attention to assure a high state of reliability. With these factors in mind, what constitutes a thorough sump flush? Are there any particular problems that the operator should be careful to avoid? What equipment can or should be used for this purpose? Finally, what items should be included in a detailed flushing procedure? Proper oil flushing of rotating equipment tends to be an afterthought. Whether it is commissioning or maintenance involving end users, construction groups or manufacturers, oil flushing tends to be thought of as a "just do it" item.Otomotifnet.com– Seiring pemakaian kendaraan, oli mesin pasti akan mengalami oksidasi akibat suhu tinggi. i dont know whether you would gather much force to lift the chards off the bottom of the box in situ or by removal with use of a "pump". The pressure should be held to a minimum 3 to 5 bar (22 to 73 psi), measured downstream from the flushing circuit, before the return line filter and sampling port. Cleaning of ball, plug, butterfly and needle valves is an important part of the hot flush process. To ensure cleanliness has been reached in all zones, the hydraulic valves should be actuated to full-stroke movement during each step of the cleaning process. A solubility enhancer when added to an in-service oil can re-adsorb system deposits such as sludge or varnish. Typically, these solubility enhancers such as Boost VR+™ and DECON™ (both with Solvancer® patent pending technology) are added to the lube oil system at least 3 months prior to an outage in addition to a filtration system such as Fluitec’s ESP™ system which can remove the dissolved degradation products from the oil. Since the solubility enhancer is compatible with the turbine oil there is no need for a sacrificial rinse. if theres fragments of metal more than the size of a 5p peice in there you should be very concerned indeed.

Oil Flushing - Let Oil Analysis Guide Your Decisions Oil Flushing - Let Oil Analysis Guide Your Decisions

Once samples from the system indicate the specified cleanliness level has been reached, continue flushing for at least 30 more minutes at turbulent flow. This increases the probability of removing adherent particles from tube walls.Select suitable system filters. New oil should be filled through a system filter or another suitable filter. Example: a hydraulic system has a flow rate and tube diameter to achieve Re=3,400 in normal service. Flushing requires a minimum of Re=4,080.

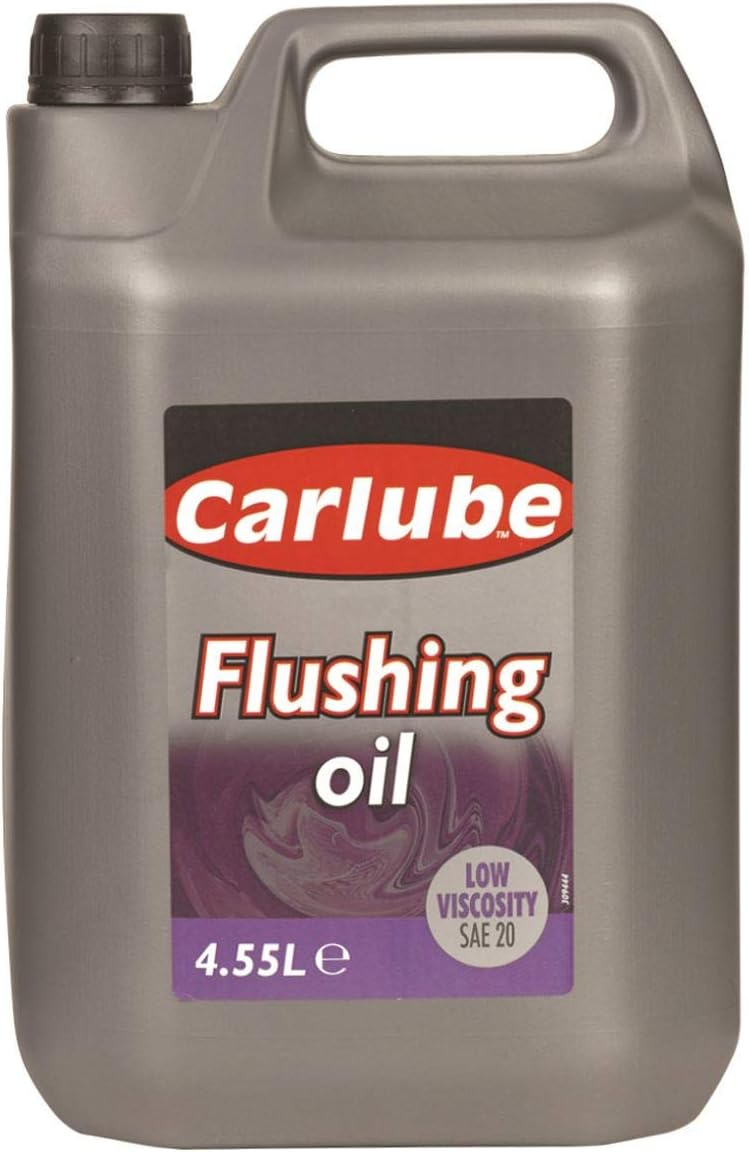

Flushing oilgood or bad?? | Technical matters Engine Flushing oilgood or bad?? | Technical matters

Often, due to system design constraints, as little as one-third of the total time is spent on the flushing activity itself. Two-thirds of the time is used to mobilize flushing equipment and workers, disassemble sensitive components, assemble by-pass lines, connect flushing hoses, preclean the flushing fluid, fill up the system and heat the flushing fluid and piping. Well-planned and well-performed flushing practices give considerable return on investment.This has been discussed many times on here and IIRC does work but can cause problems on old and high mileage cars by dislodging crud that has previously been keeping oil seals leak free. By cleaning the engine prior to installing fresh oil, you ensure the new oil functions as intended and delivers maximum protection. The oil won’t last as long or protect as well if it must contend with sludge and deposits from the previous oil.

Great Deal

Great Deal