About this deal

Normally epoxies should show resistance towards, water, sunlight, chemicals and fires. So, first decide what type of resistance should your epoxy show? Give points only based on those. While it is common to associate polyester resins and epoxy resins, their properties are sufficiently different that they are properly treated as distinct materials. Polyester resins are typically low strength unless used with a reinforcing material like glass fibre, are relatively brittle unless reinforced, and have low adhesion. Epoxies, by contrast, are inherently strong, somewhat flexible and have excellent adhesion. However, polyester resins are much cheaper. May, Clayton (2018). Epoxy Resins: Chemistry and Technology (2nded.). CRC Press. p.65. ISBN 978-1-351-44995-3. An important criterion for epoxy resins is the Epoxy value which is connected to the epoxide group content. This is expressed as the " epoxide equivalent weight", which is the ratio between the molecular weight of the Rorar and the number of epoxide groups. This parameter is used to calculate the mass of co-reactant (hardener) to use when curing epoxy resins. Epoxies are typically cured with stoichiometric or near-stoichiometric quantities of hardener to achieve the best physical properties.

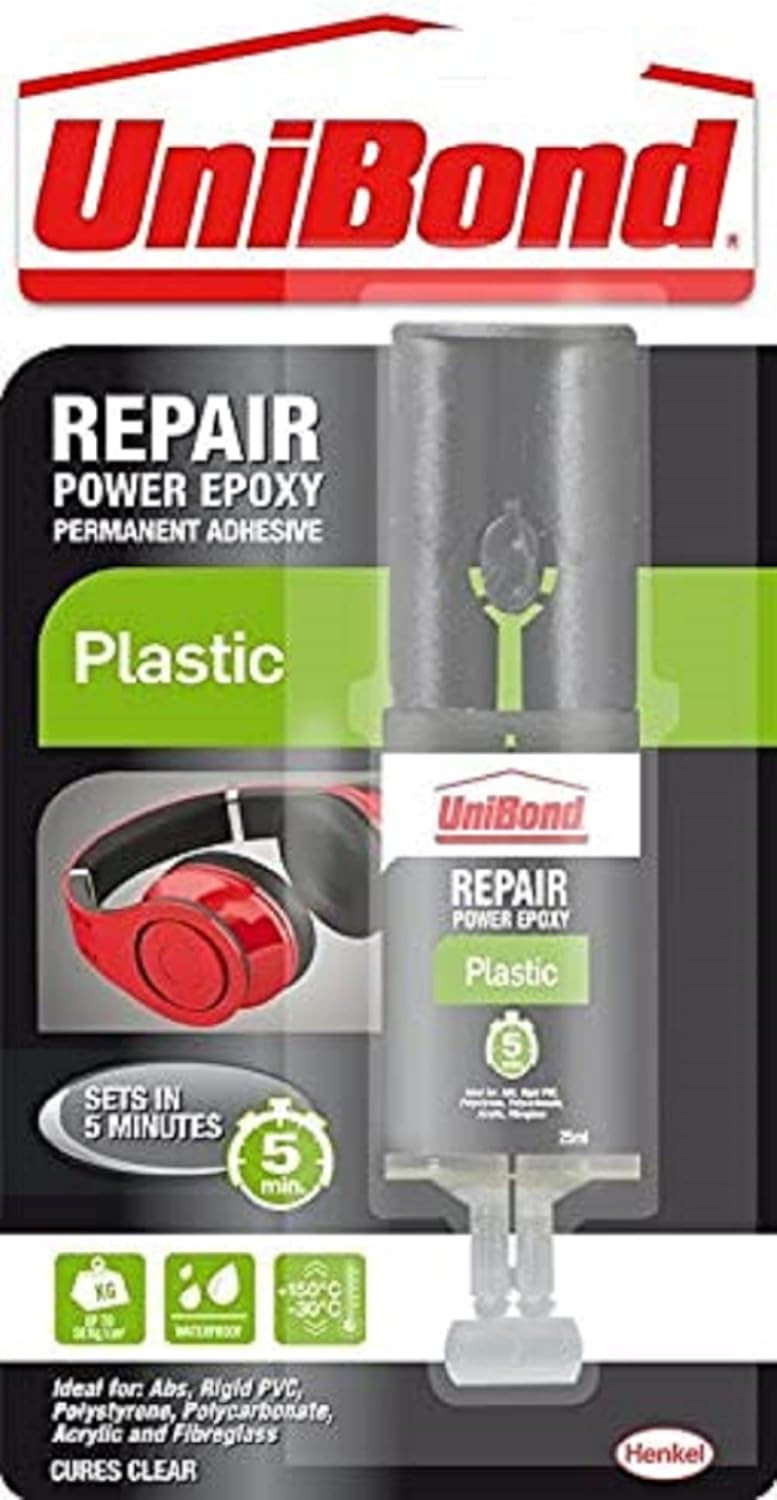

Key specs – Type: Liquid plastic; Dry colour: Clear; Volume: 4ml; Consistency: Liquid; Curing time: N/A; Water resistant: Yes Sukanto, Heru; Raharjo, Wijang Wisnu; Ariawan, Dody; Triyono, Joko; Kaavesina, Mujtahid (2021-01-01). "Epoxy resins thermosetting for mechanical engineering". Open Engineering. 11 (1): 797–814. Bibcode: 2021OEng...11...78S. doi: 10.1515/eng-2021-0078. ISSN 2391-5439. S2CID 235799133.

1. A Fan-Favorite Super Glue For Most Plastics

Tian, Xiaodong; Geng, Ye; Yin, Dongqing; Zhang, Baolong; Zhang, Yuying (2011-02-01). "Studies on the properties of a thermosetting epoxy modified with chain-extended ureas containing hydroxyl-terminated polybutadiene". Polymer Testing. 30 (1): 16–22. doi: 10.1016/j.polymertesting.2010.09.011. ISSN 0142-9418. Monte, Salvatore J. (1998), Pritchard, Geoffrey (ed.), "Diluents and viscosity modifiers for epoxy resins", Plastics Additives: An A-Z reference, Polymer Science and Technology Series, Dordrecht: Springer Netherlands, vol.1, pp.211–216, doi: 10.1007/978-94-011-5862-6_24, ISBN 978-94-011-5862-6 , retrieved 2022-03-09 Polyester epoxies are used as powder coatings for washers, driers and other "white goods". Fusion Bonded Epoxy Powder Coatings (FBE) are extensively used for corrosion protection of steel pipes and fittings used in the oil and gas industry, potable water transmission pipelines (steel), and concrete reinforcing rebar. Epoxy coatings are also widely used as primers to improve the adhesion of automotive and marine paints especially on metal surfaces where corrosion (rusting) resistance is important. Metal cans and containers are often coated with epoxy to prevent rusting, especially for foods like tomatoes that are acidic. Epoxy resins are also used for decorative flooring applications such as terrazzo flooring, chip flooring, and colored aggregate flooring.

We have given all the features and benefits of these 10 products. We’ve discussed what you’ll get after using each product. However, we understand that it’s like a maze to you. But don’t fret. We’re here to guide you to the product that best matches your needs. Epoxy adhesives have many different qualities, including heat resistance and chemical resistance. And yes, there are also waterproof epoxy options for using on leaks, pools, and plumbing solutions. Schulenburg, Jan Olaf; Kramer, Andreas (2004). "Structural Adhesives - Improvements in Vehicle Crash Performance". SAE Transactions. 113: 111–114. ISSN 0096-736X. JSTOR 44699912. In that case, you have to follow a step by step method. At first identify the material types. For example let’s say that you’ve got steel and plastic. Next, do a search for the word steel in our article. See if it’s mentioned in any product specifically. Epoxy resins typically require a precise mix of two components which form a third chemical to get the stated properties. Depending on the properties required, the ratio may be anything from 1:1 or over 10:1, but in usually they must be mixed exactly. The final product is then a precise thermoset plastic. Until they are mixed the two elements are relatively inert, although the 'hardeners' tend to be more chemically active and should be protected from the atmosphere and moisture. The rate of the reaction can be changed by using different hardeners, which may change the nature of the final product, or by controlling the temperature.

Normal gelcoat formulated for use with polyester resins and vinylester resins does not adhere to epoxy surfaces, though epoxy adheres very well if applied to polyester resin surfaces. "Flocoat" that is normally used to coat the interior of polyester fibreglass yachts is also compatible with epoxies. Compatible Materials: Leather, cork, paper, cardboard, wood, chipboard, fabric, metal, ceramic, rubber, plastic, plexiglass, polycarbonate, polystyrene, PVC, polyethylene, polypropylene and polytetrafluoroethylene Epoxy adhesives need to be mixed to a specific ratio otherwise they won’t work. Adding more hardeners won’t increase durability or strength. There is only one level of durability that each epoxy resin can cure at.

The best epoxy for plastic is the more durable option when it comes to adhesives, as it can withstand temperatures, UV light, solvents, and can endure a measure of force. We can now move on to some pros and cons of using a two-part epoxy adhesive. Most of the commercially used epoxy monomers are produced by the reaction of a compound with acidic hydroxy groups and epichlorohydrin. First a hydroxy group reacts in a coupling reaction with epichlorohydrin, followed by dehydrohalogenation. Epoxy resins produced from such epoxy monomers are called glycidyl-based epoxy resins. The hydroxy group may be derived from aliphatic diols, polyols (polyether polyols), phenolic compounds or dicarboxylic acids. Phenols can be compounds such as bisphenol A and novolak. Polyols can be compounds such as 1,4-butanediol. Di- and polyols lead to glycidyl ethers. Dicarboxylic acids such as hexahydrophthalic acid are used for diglycide ester resins. Instead of a hydroxy group, also the nitrogen atom of an amine or amide can be reacted with epichlorohydrin. Also known simply as polythene, the high density version has a high strength to density ratio and is commonly used for a wide variety of applications, from milk bottles to toys. Plastic epoxy is moldable, can be used on damped surfaces and also on water. It comes in two part adhesive and is supposed to be mixed before glueing anything. It’s a perfect gap filler for all types of materials. What Do People Like About Plastic Epoxy? To save you some time (and possibly some heartache), here’s what you need to know about adhesives and plastics.Additionally, it can be used for O-ring bonding. One customer wrote, “ I have used it on virtually every type of hard plastic found in toys, kitchen appliances, fasteners, tools, you name it and never failed to get a strong, long-lasting bond.” It requires mixing two parts together, so you will need some knowledge and precision mixing and understanding the ratios Solvent Cement:Unlike typical adhesives, solvent or poly cement can dissolve the material itself to use it to bond plastics and other surfaces. Something like an industrial-grade solvent cement will create a higher tensile strength.

Great Deal

Great Deal